Product Description

Product Description

Premium Ice Machine Condenser – Reliable Heat Exchange for Commercial Ice Production

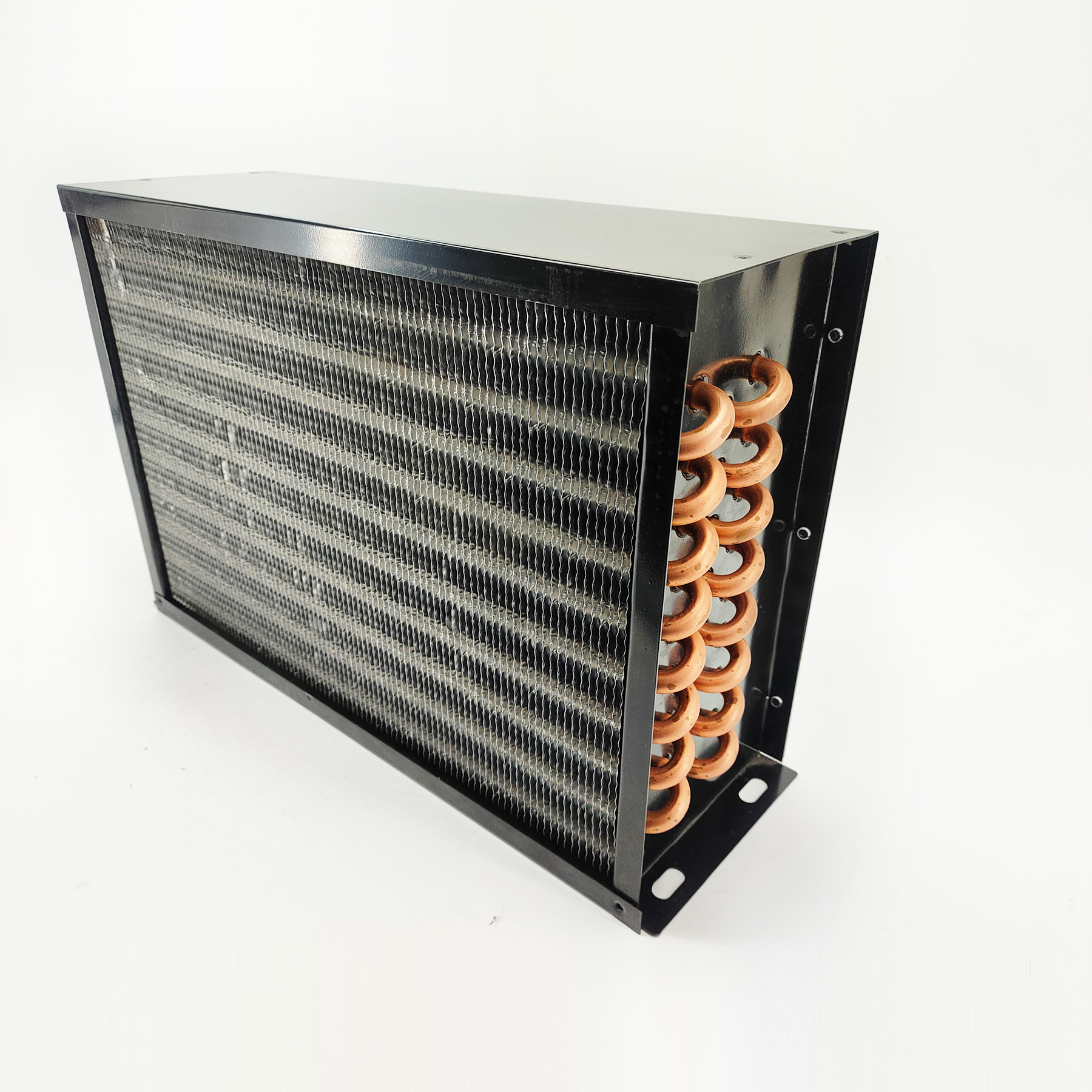

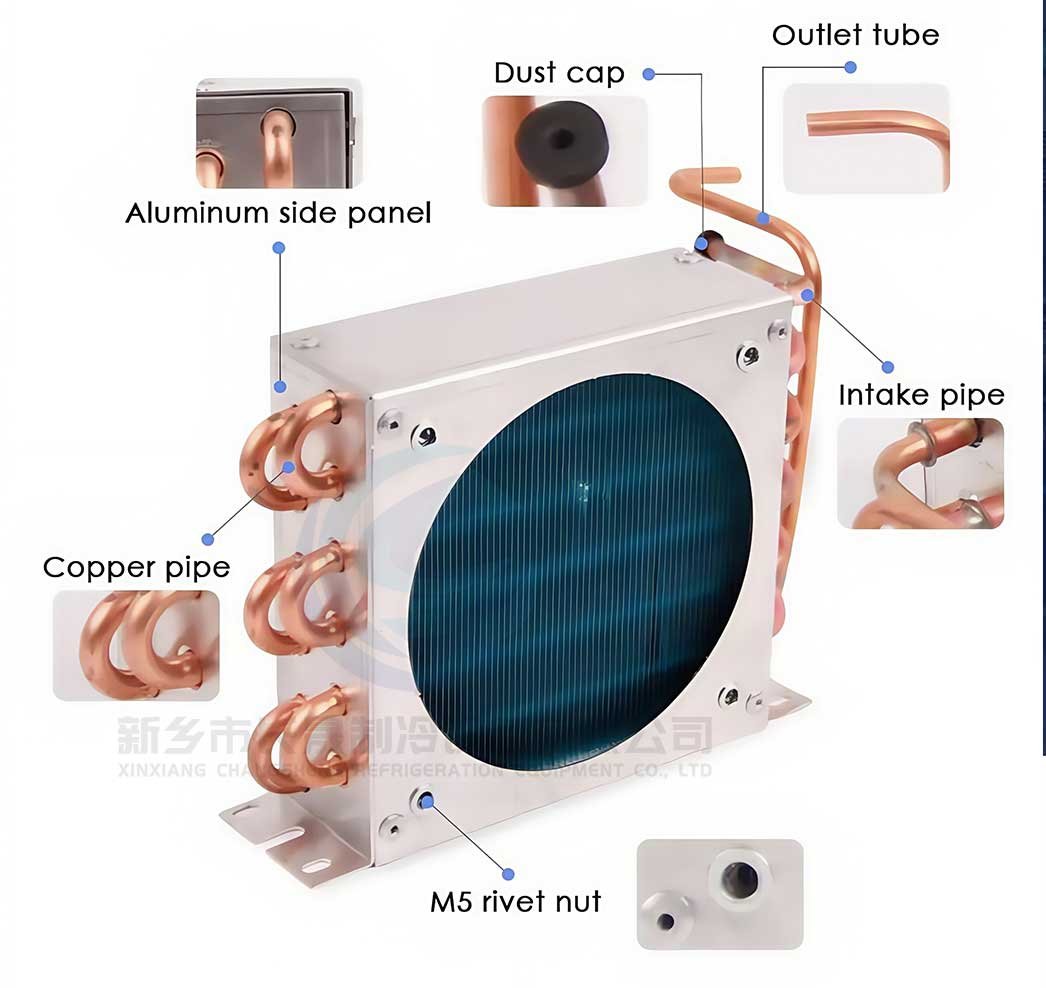

The Ice Machine Condenser is a critical component in commercial ice makers, designed to efficiently remove heat from refrigerant during the ice production cycle. Our condensers feature heavy-duty copper tubing with aluminum fins for optimal heat transfer in demanding environments like restaurants, hotels, and food processing facilities.

Key Features & Benefits:

Key Features & Benefits:

✔ Superior Heat Dissipation – Precision-designed fin pattern maximizes airflow

✔ Commercial-Grade Durability – Corrosion-resistant copper tubes with protective coatings

✔ Wide Compatibility – Works with R-404A, R-134a, and other common refrigerants

✔ High Pressure Rating – Tested to 500 PSI for reliable operation

✔ Easy Maintenance – Cleanable fin design reduces downtime

Technical Specifications:

Technical Specifications:

-

Tube Material: 99.9% pure copper (3/8″ to 5/8″ OD)

-

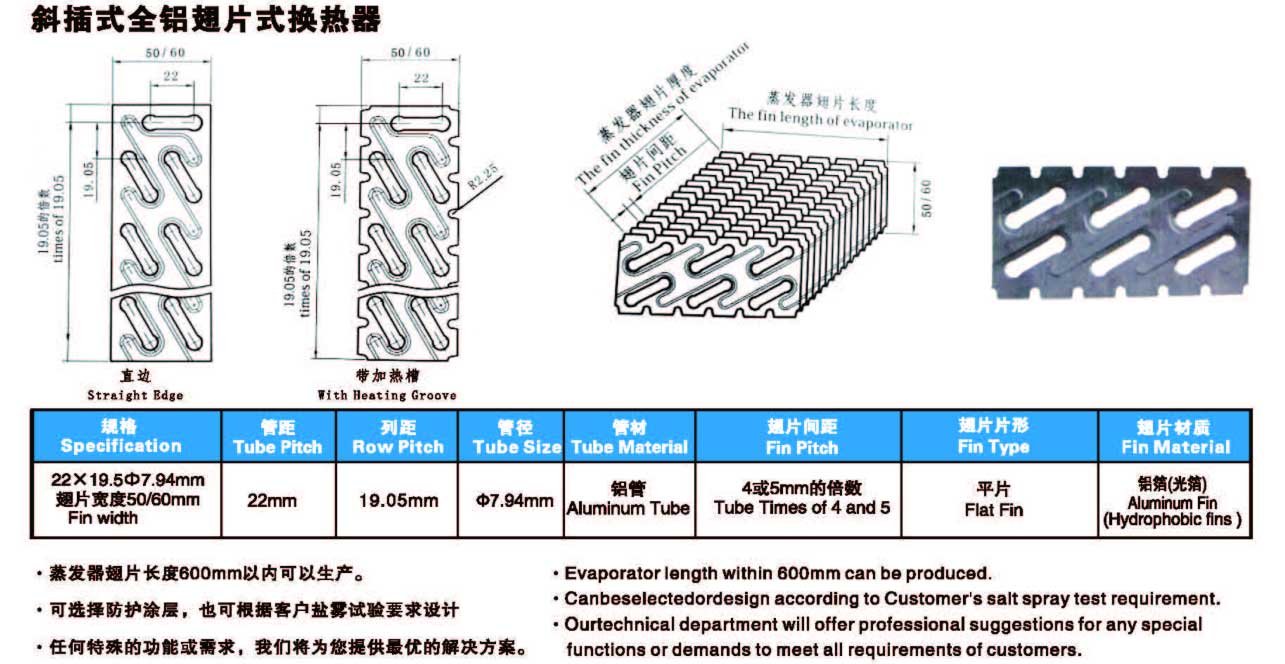

Fin Material: Hydrophilic aluminum (0.004″-0.006″ thickness)

-

Fin Density: 12-16 fins per inch (standard)

-

Operating Pressure: Up to 500 PSI

-

Temperature Range: -40°F to 200°F

Applications:

Applications:

-

Undercounter ice machines

-

Modular ice makers

-

Ice flakers and nugget ice machines

-

Commercial refrigeration systems

Why Choose Our Ice Machine Condenser?

Why Choose Our Ice Machine Condenser?

✅ 30% Better Heat Transfer than standard condensers

✅ OEM Replacement Quality with exact fit specifications

✅ Energy Efficient Design reduces operating costs

✅ 5-Year Limited Warranty for peace of mind

FAQ

Q1: How is quality ensured?

A1: we have a one year quality warranty B L issue date. If the product does not work property as described, and the problem is proven to be at our fault, we will provide exchange services for the same specific item.

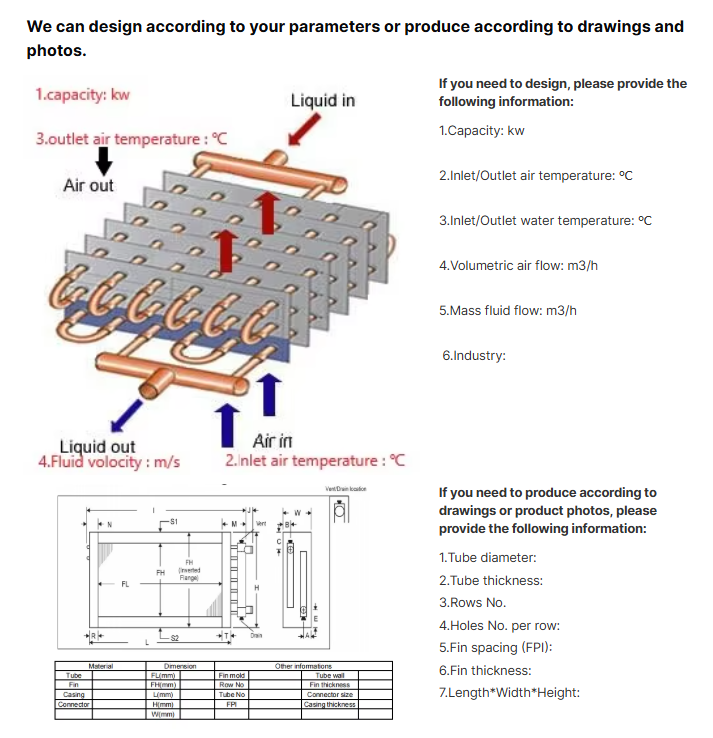

Q2: Do you provide OEM or ODM service?

A2: Yes. We can produce G-air standard products under customer brand or modify the products to satisfy customers personalized requirements, or work together with customer to design and produce a totally new products.

Q3: How long can I get the feedback after sending the inquiry?

A3:Usually you will get feedback within 30 minutes during the office hours and 12 hours after office hours.

Q4: How long is the production lead time?

A4: Usually the production lead time will be 20 days once order confirmed. Sometimes we have a few.

Q5: How do you make our business long-term and good relationship?

A5: We keep good quality and competitive price to ensure our customers benefit , We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.